This is Decathlon! We visited the birthplace of the French sports equipment manufacturer, and toured the BTWIN Village, including the design studios and production hall. From BTWIN to Riverside and Rockrider to VAN RYSEL, exciting new products are being developed in Lille. And we witnessed a shift in focus towards improving performance.

The French Dream – From Lille to the world

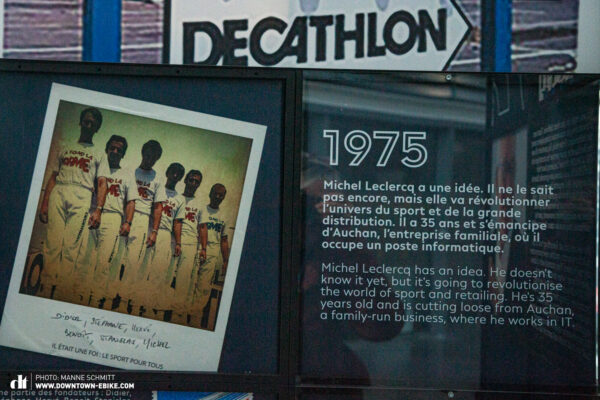

Decathlon have gained international recognition far beyond the borders of Europe. We set out to discover the secrets behind the success of this French sporting goods giant and to understand their vision. Our destination was the BTWIN Village in the north of France. Lille, where Decathlon have their headquarters, is the birthplace of the company – a charming, historic city of around 235,000 inhabitants. Decathlon was founded nearly 50 years ago in 1975 with a mission to democratise sport, make it accessible to all, and promote a healthy, active lifestyle. Today, the brand offer equipment for more than 100 sports through more than 1,700 stores in 60 countries. Through pop-up stores, Decathlon also venture into remote regions, such as Senegal, with the aim of making different sports accessible to local communities.

In addition to incorporating emerging markets into their sales network and creating jobs, Decathlon place great importance on the development of their employees through ongoing training and retraining initiatives. The company are increasingly focusing on sustainability in both production and development. With the aim of becoming carbon neutral by 2050, Decathlon are working closely with their suppliers, actively promoting the circular economy and gradually converting their branches to sustainable energy sources. This commitment extends to Decathlon’s bike manufacturing facilities, which account for a significant proportion of the group’s energy consumption, with more than 3 million bikes sold in Europe each year.

The village in the city – BTWIN Village

The Lille site is more like a small town than a traditional office or factory building. As well as design studios, laboratories and a production hall, the complex, which was once a cigarette factory, now also houses a gym, a bar, a children’s play area, several restaurants and, of course, a Decathlon store. Outside and even inside the building, cycling classes are offered for children, and there are also facilities for playing padel, table tennis or trying out skateboarding. The BTWIN Village is designed as an intergenerational space that breaks down the traditional division between work and leisure. The focus is on fostering team spirit and embracing sustainability. And this works! Many employees come to the BTWIN Village by bike and even can roll right up to their desks.

The BTWIN Village is not only a bicycle factory and a place for leisure activities, but also a development and design centre for bikes and their components. We were able to take a closer look at the different areas and discover some exciting developments. For example, Decathlon are currently developing a GPS tracker to prevent bike theft. Although not a new concept in itself, this tracker will act as a sort of dead man’s switch. If the tracker is disconnected or forcibly removed, the bike will be rendered inoperable. The engineers at BTWIN Village have also developed their own motor concept, which is designed to increase range through higher voltage.

Exciting new bikes and other products have also been introduced within the various brand segments. These include a Long John cargo bike to complement the BTWIN Cargo R500E Longtail, a new race mountain bike priced up to € 6,000 that the Decathlon Racing Team have been riding in international UCI races this year, and a full-suspension enduro e-mountain bike with 170 mm of travel. The road and gravel brand VAN RYSEL, is only 4 years old and means “he who comes from Lille” in Flemish, but it has already developed triathlon bikes, home trainers, as well as UCI-compliant racing bikes.

Development at Decathlon

Decathlon have traditionally focused on the production of affordable, mass-produced bikes. However, there is a gradual shift towards internal innovation and mobility solutions. At the BTWIN Village, numerous test labs and design studios are dedicated to developing new bikes and pioneering concepts for the bicycle industry. These facilities are organised into five teams, each specialising in targeting specific development: road bikes, mountain bikes, touring bikes, city bikes and kid’s bikes. The teams are constantly fed fresh ideas from the in-house Innovation Hub, focusing on advances in new materials and manufacturing processes for batteries, grips, saddles and more.

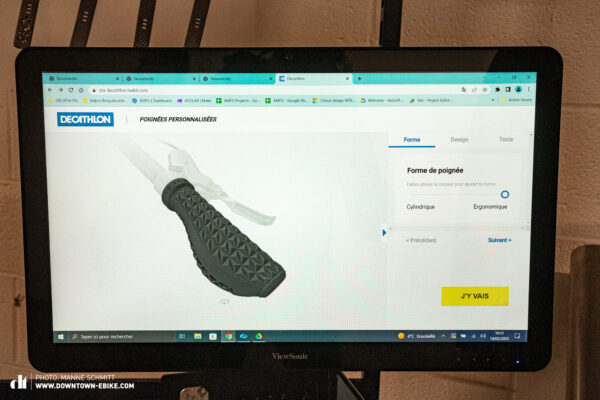

The development of new bikes at Decathlon is based on the company’s own ideas, complemented by insights into social trends and consumer needs. Innovations, whether for complete bikes or individual components, are developed and tested both within the company and in collaboration with various partners. When a new idea emerges, the first prototypes, called “monsters”, are made from old bikes and parts from various products. These prototypes serve as an initial visualisation of the new product ideas and help to identify key issues at the planning stage. As the design process progresses and the new bike undergoes various laboratory tests, it becomes more defined. Decathlon use 3D printing for the first prototypes, which allows them to quickly test new products in terms of shape, attachment points and compatibility. At the final stage of the design process, prototypes are made and rigorously tested in the laboratory until they are ready for final production. These tests include vibration, temperature, weight and a crash simulation.

Decathlon’s entire development process takes place in a single location: Lille. This approach saves time and travel, facilitates seamless collaboration between the various teams and is in line with sustainability goals. Bike production is also predominantly local – 90% of the bikes sold by Decathlon in Europe are manufactured in Europe in keeping with the motto “local for the locals”. Beyond the macro level, Decathlon get down to the nitty-gritty to find smarter and more sustainable solutions. For example, they use reusable Velcro strips instead of cable ties for bike packaging, and custom-designed boxes that fit DHL’s standard dimensions. Decathlon’s commitment to sustainability extends beyond production. They offer post-sale support by 3D printing customised spare parts for products that are no longer in stock. They have also adopted the “Second Life” concept, which allows second-hand markets for bikes and equipment , including repair shops, to operate within Decathlon stores.

Quality vs. price – The Decathlon deal

At Decathlon, low prices do not mean low quality. We asked how Decathlon manages to keep the prices of their bikes so low while complying with all the standards – and in some cases even surpassing them. The answer is, at first, disappointingly vague: “A combination of several price-reducing factors”. Markus Wirth, Commercial Director at Decathlon Germany, then goes into more detail. He explains that the design process is kept as long as necessary and as short as possible. Less emphasis is placed on weight, geometry and aesthetics and more on price-conscious development. In addition, models are not discontinued every year, but are on offer for several years. Of course, the equipment package also contributes to the attractive price of the bikes because the focus is on cost-effective features, especially for the entry-level models. In addition, the bikes are produced in relatively large quantities and with a high degree of vertical integration, meaning that Decathlon develop and manufacture many parts themselves.

With the introduction of new models, some of which are under development and some of which have already been unveiled, Decathlon’s approach and pricing strategies are undergoing a slight change. Attributes such as design, weight, geometry, aesthetics and features will no longer be considered solely on the premise of “fast and cheap”, but rather according to their intended purpose. The result of this repositioning is the new carbon RCR model, available for € 4,799 – still comparatively affordable, but in a different league to the original Decathlon bikes. So is this a move towards high quality at attractive prices? We will be watching with interest to see whether customers welcome this new positioning.

Admittedly, we were a little prejudiced before our visit and our expectations of the Decathlon bikes were a little like Lille’s fickle weather: sometimes okay, sometimes not so great. However, after two full days, including an extensive tour of the BTWIN Village and several test rides, we are now convinced that Decathlon’s new approach holds promise. The company continue to excel at delivering exceptional value for money. And, at the same time, the French sports equipment manufacturer are ushering in a new era through their own innovations and the expansion of their product range.

Words: Gabriel Knapp Photos: Manne Schmitt